Contents

- 1Introducing the Corsair CX550M

- 1.1Packaging and accessories

- 2Connectors & cabling

- 2.1Casing & cooling

- 3Input filtering

- 4Primary side

- 4.1+5 V stand-by rail

- 5Secondary side

- 5.1Build quality

- 6Load testing

- 6.1Loading +5 V SB

- 6.2Voltage hold-up time

- 6.3Combined loading

- 6.4Combined loading ripple

- 6.5Crossloading, overloading

- 6.6Crossloading, overloading ripple

- 6.7Fan speed, temperatures and noise

- 7Conclusion and evaluation

- 7.1Bonus

- 7.2Thanks

- 7.3Discussion

Conclusion and evaluation

The Corsair CX550M delivered power both under combined loading and crossloading, but it did not pass the combined and crossload testing in accordance with the ATX specification, so according to my evaluation methodology, it is not deserving of an evaluation. Upon first glance, the unit manages to deliver the voltage hold-up time of more than 10 ms. But because of a too lowly-rated bulk input capacitor, the power good signal does not, and upon further testing with a precise AC supply interruption, it is clear to me that the voltage doesn’t even stay in spec unless the hold-up time is much shorter. So short in fact that it may pose a risk of instability even if you actually use a UPS in conjunction with the power supply. Of course you can just buy a much higher-rated model, like the CX750M. But why do that? Why not just get a higher-end series with lower power at a similar price point?

Another thing which seems very strange to me are the protections. Corsair only states that there is the OPP present. I found no such thing, the unit never reacted to overload and shut down when the voltage @+12 V fell under 9.5 V. This is more like a joke than protection to me. On the other hand I found the CX550M has OTP. It has also been reported there is in fact OCP working on the +3.3 and +5 V rails (most likely through the Anpec buck controller). So the advertised protections work at “meh” rate at best while there are other protections present which seem to work but are not advertised. This is kinda strange.

What I like about the series is that thanks to the DC–DC modules used, the regulation easily reaches the high-end class. It’s pretty much fantastic. Also the efficiency is really very good. However the ripple suppression hardly falls to within the margins of my mainstream requirements, and the −12V regulator has a difficult time keeping up with the high-speed fan connected to it. The thing is, there are huge differences in pricing. With discounts, the CXM is so damn cheap (and that includes shipping) in the US (I have seen it for 40 US dollars with shipping) that even with all corner-cutting, this unit still makes a lot of sense from a financial standpoint. For the money, there is simply nothing else that matches it. But here in Europe where the price is easily more than twice as high you just expect better performance. And some competing series (like the Cooler Master GM) have that. Corsair units perform great in the high-end, but it seems as though their mainstream still just doesn’t get things right.

Pros Pros |

+ modular cabling + very good voltage regulation + 5-year warranty + good efficiency + OK build quality + silent + working OTP |

Cons Cons |

− mediocre ripple suppression − over power protection not working − under voltage protection not working − hold-up time way out of spec − bad capacitors |

Be aware of… Be aware of… |

/?\ |

Bonus

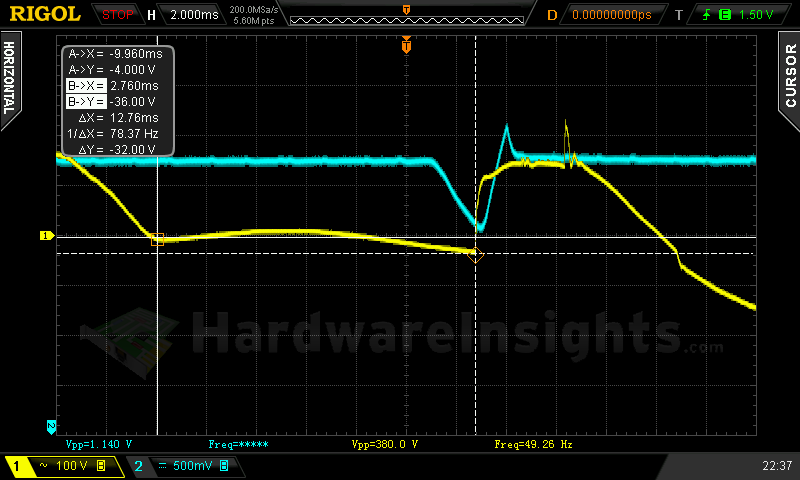

I had some time before this article got published, so I went ahead and did some more testing. Firstly, I put in a big old Rubycon, I think MXR was the series, 270/400 capacitor in the unit. With this, the hold-up time under the conditions of the third hold-up time test increased by more than one third to 12.76 ms. This is already a much better result.

I also had a look at the +5 V SB/+12 V ripple and it was clearly the lowest with this input capacitor.

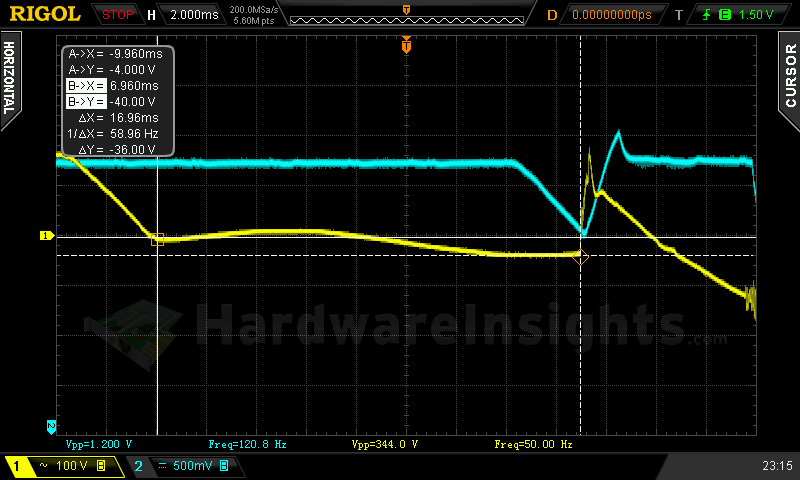

Putting another capacitor in, another old one, a Jamicon HS 330/400, increased the hold-up time to almost 17 ms, as it should be. I think we can pretty much call this being in spec.

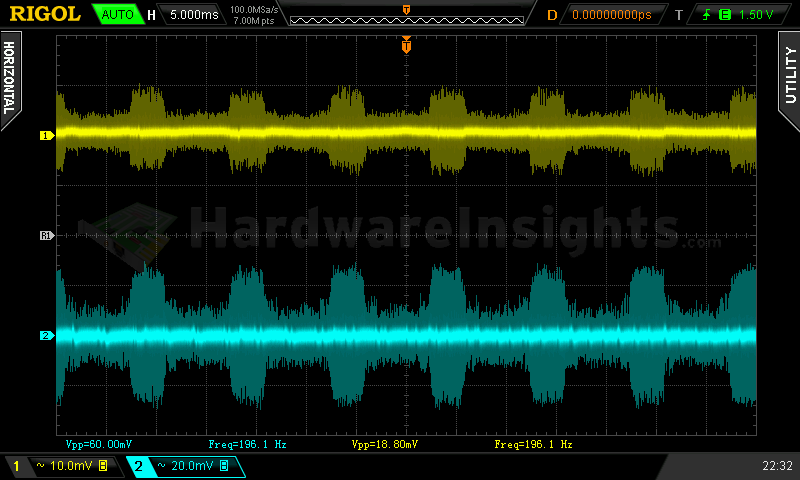

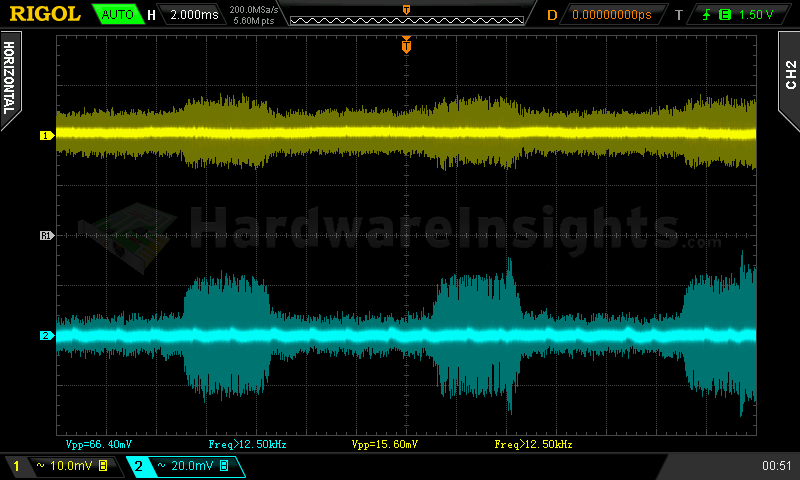

However, the ripple increased by a significant margin. I then put an NCC KYB 3300/6.3 on the +5 V SB output with a combination of custom KZN 3300/16 and Samxon RS 3300/16 to the +12 V, together with an NCC PSA 100/16 polymer on the modular board. This itself did not help that much so I also put two X7R 10/16 ceramics on the modular board on one vacant spot. This brought the ripple to slightly higher than it was with the Rubycon 270/400, but on average lower than with the original capacitors CWT put in.

This implies that not only the bulk input capacitance, but also other factors like ESR of even an input bulk capacitor may play a role. As per my measurement, the Rubycon had the lowest ESR of all. So there may be something there worth investigating further. Also, there may be something relevant here with regard to capacitor noise (there are specialised audio caps that suppress noise after all). Here are the results:

- original caps (Nichicon GG 220/400, measures 196/0.30 Ω, no ceramics): worst ripple, poor HUT

- Jamicon HS 330/400, measures approx. 310/0.20 Ω; recapped secondary: slightly better ripple, best HUT

- Jamicon HS 330/400; recapped secondary+ceramics: better ripple, best HUT

- Rubycon MXR 270/400, measures approx. 222/0.15 Ω: best ripple, better HUT

I also noticed one more thing, something very interesting in fact which I’ve not noticed before (as I have not been looking for it) in similar cases. I am not sure whether the greatest impact was from the higher-capacity bulk cap, or the output caps. However, from just a quick overview, the efficiency after all the changes improved by as much as 1.5–3 %!! Now the efficiency could easily pass 80 PLUS Silver. Clearly, the unit now does a lot less switching somewhere while the output performance is pretty much the same. That (how much switching the unit does) may in fact also affect the ripple values. This is also consistent with reports (which seemed strange at first) from users citing not only their improved stability, but also the amount of heat generated by CPUs and graphics cards had often improved considerably by just replacing old units (like Corsair VS, CX and similar series from competition) with high-end ones. Which among other things usually have much higher input and output capacity, lower ripple and all the other “certainties and social prosperities”. I think this proves there may be some merit to it.

So in the end it may be very well possible that if CWT put proper capacitors in the unit, they could have went with cheaper transistors for the same efficiency but overall better performance (including hold-up time). I would draw an analogy to this with bigger-sized decent car engines compared to downsized, lawn-mower engines: people often find that bigger engine not only has the same fuel consumption as the small one in the end, but it is also under a lot lower overall stress (thus you get better life expectancy) and you also have much more power, simply unavailable from a small engine. So back to this power supply, by using smaller and higher-ESR caps the end result has the impact on much more aspects of the final performance that one could have expected. CWT had to use better (and more expensive) transistors to compensate for the lack of capacity…which in turn drove the price back up anyway…and in this manner we can continue.

I think the now retired engineers back in the ’80s were not dumb and there clearly is some merit to the rules of thumb which were made back then, like 1 output W should equal 1 μF of input bulk capacity. Today the fashion is to make the most of the least so you can always read in the Champion Micro datasheets how better this new generation of PFC/PWM controller is and how now you need an even smaller bulk cap than before and it will still work. Well, they won’t tell you that you may expect worse efficiency, more stress on the components and definitely worse hold-up time. All the old engineers will tell you that at least for the old half-bridge platforms, if the bulk capacity is not there, the unit will not deliver the rated power no matter what. The same way it will not deliver the power if the transistors are too weak, if the heatsink is too small or if the transformer is too small. The technology has advanced and of course the platforms are better. But there are still certain thresholds you simply cannot cross, and putting 220μF capacitor in 550W 80 PLUS Bronze certified unit is clearly far behind one of such.

So by simply putting a few bigger caps into the CX550M, I have made a more efficient unit out of it, which passes on hold-up time just fine and also has slightly better ripple suppression.

Thanks

I thank the Corsair company for providing the Corsair CX550M unit.