Contents

- 1Introducing the Corsair HX750i

- 1.1Packaging and accessories

- 2Connectors & cabling

- 2.1Casing & cooling

- 3Input filtering

- 4Primary side

- 4.1+5 V stand-by rail

- 5Secondary side

- 5.1Build quality

- 6Load testing

- 6.1Loading +5 V SB

- 6.2Hold-up time

- 6.3Combined loading

- 6.4Combined loading ripple

- 6.5Crossloading, overloading

- 6.6Crossloading, overloading ripple

- 6.7Fan speed, temperatures and noise

- 7The Link

- 7.1The application

- 8Conclusion and evaluation

- 8.1Thanks

- 8.2Discussion

Connectors & cabling

All the wires are molded together to form flat ribbons. The most important difference over RMx/RMi is that HXi cabling has no feedback wires for voltage regulation (other than the obligatory +3.3 V) and also no cable capacitors. Most of the wires in the cabling are 18AWG only, with the exception of molex-to-Berg adapters which have 20AWG, and the PCIe cables. Those have 8 wires 16AWG for their first connector, and then 8 parallel 18AWG wires on that. That’s not ideal but I won’t deduct many points for that. What’s worse, both the 150W connectors share single point of failure in the EPS connector used on the modular board. There, only 3 pins are shared for +12 V (and four for ground as two wires are pressed into one pin). So basically three pins are there to transport 300 W nominal (8.3 A per pin). That would still be acceptable if at least the pins were gold-plated, but guess what…they are not.

The molex connectors are equipped with clips for easier unplugging. The Berg pins are even made from pure brass with no fine metal plating at all. Maybe it would be better to only provide four PCIe connectors, but actually make the pins properly gold-plated. Because all this cabling is good for transporting about 2 kW at its maximum rating…if it had quality contacts and wire thickness for it. So if you’ll only need 750 W, but over just few cables, this unit is not really good for that. This unit is designed to provide all the power on the cabling combined, with about 1/3 rated draw from each. Less is sometimes more! Also the USB Link cable wastes one of the two USB lines in a USB 2.0 motherboard header. This is the same situation as with the Enermax Digifanless we reviewed last year. Once again, I understand the reasoning behind this, but it’s still a waste…

In total, we have:

- 1× Main ATX (20+4pin): 60 cm

- 2× ATX 12 V (4+4pin): 65 cm

- 6× PCIe (6+2pin): 3× 60 cm, 3× 74 cm

- 12× SATA: 3× 50 cm, 3× 61 cm, 3× 72 cm, 3× 83 cm

- 8× peripheral molex: 2× 44 cm, 2× 54 cm, 2× 64 cm, 2× 74 cm

- 2× adapter molex-to-Berg for FDD: 10 cm

- 1× Mini USB-B to USB 2.0 header: 80 cm

- 1× Corsair Link digital cable: 79 cm

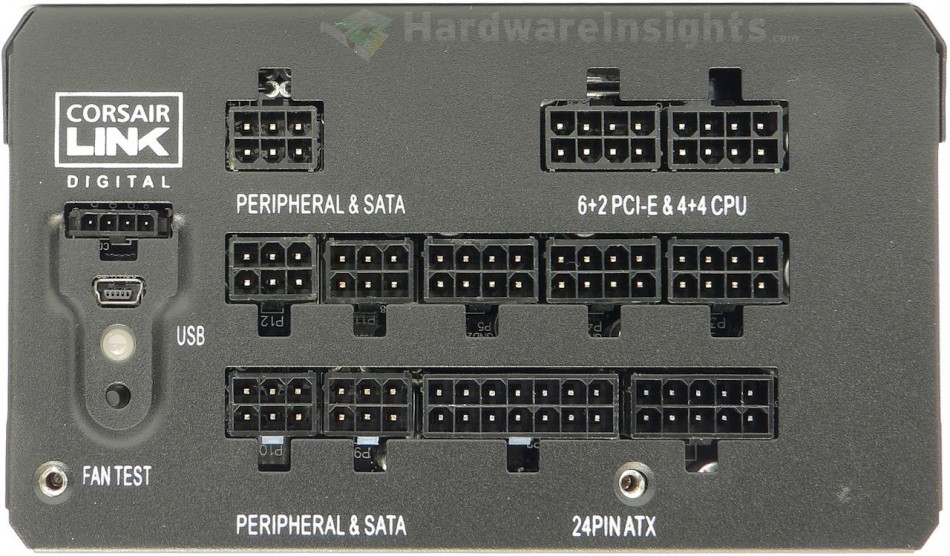

We can see the modular cabling board uses 6pin PCIe connectors for peripherals and EPS for PCIe/ATX 12 V cables. Besides the USB interface, there is also a digital interface to connect the unit through water-cooling set and save one USB cable. There is also fan test button to test whether your fan is actually working.

Casing & cooling

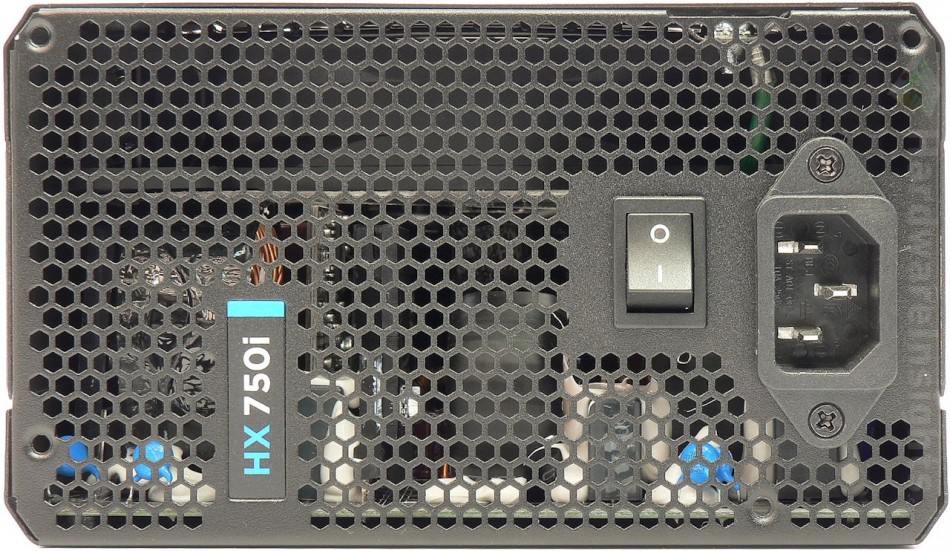

The metal chassis of the HX750i is made out of only 0.8mm SECC steel, and it has a matte black finish (which is most likely a powder coating). However, thanks to the mechanical processing, it is quite tough anyway. The bent edges of the unit seem to not be so useless after all as they seem to add to overall chassis endurance. You may notice the upper part of the chassis uses the same style as the RM550x. A wire fan grill is used and it forms an impression of continuity with the line-styled depression chassis.

The backside is also similar, there is the usual hexagonal mesh pattern there. There is enough space even under the input receptacle and switch. You may notice the spot on the primary side of the mesh again where the model name is located. It may actually also make some sense as with this spot blinded, the outcoming air is forced to pass around, cooling the input rectifier on the way.

The fan is different this time, NR135P. While it seems almost the same and has the same maximum speed (1500 RPM), it uses fluid dynamic bearing instead of rifle bearing. This is most likely the most advanced system of self-lubricating sleeve bearing. It also has slightly higher rated airflow of 78.71 CFM (static pressure of 2.16 mm water column) but also higher noise (32.5 dBA). The rated lifetime is now 50,000 hours at 40 °C.