Contents

- 1Introducing the Modecom Volcano 750 Gold (ZAS-MC90-SM-750-ATX-VOLCANO-GOLD)

- 1.1Packaging and accessories

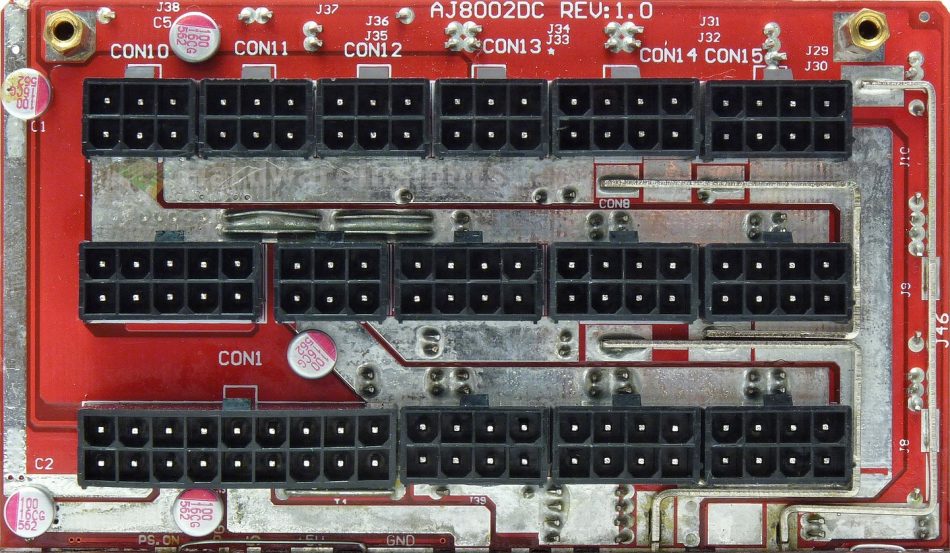

- 2Connectors & cabling

- 2.1Casing & cooling

- 3Input filtering

- 4Primary side

- 4.1+5 V stand-by rail

- 5Secondary side

- 5.1Build quality

- 6Load testing

- 6.1Loading +5 V SB

- 6.2Hold-up time

- 6.3Combined loading

- 6.4Combined loading ripple

- 6.5Crossloading, overloading

- 6.6Crossloading, overloading ripple

- 6.7Fan speed, temperatures and noise

- 7Conclusion and evaluation

- 7.1Thanks

- 7.2Discussion

Secondary side

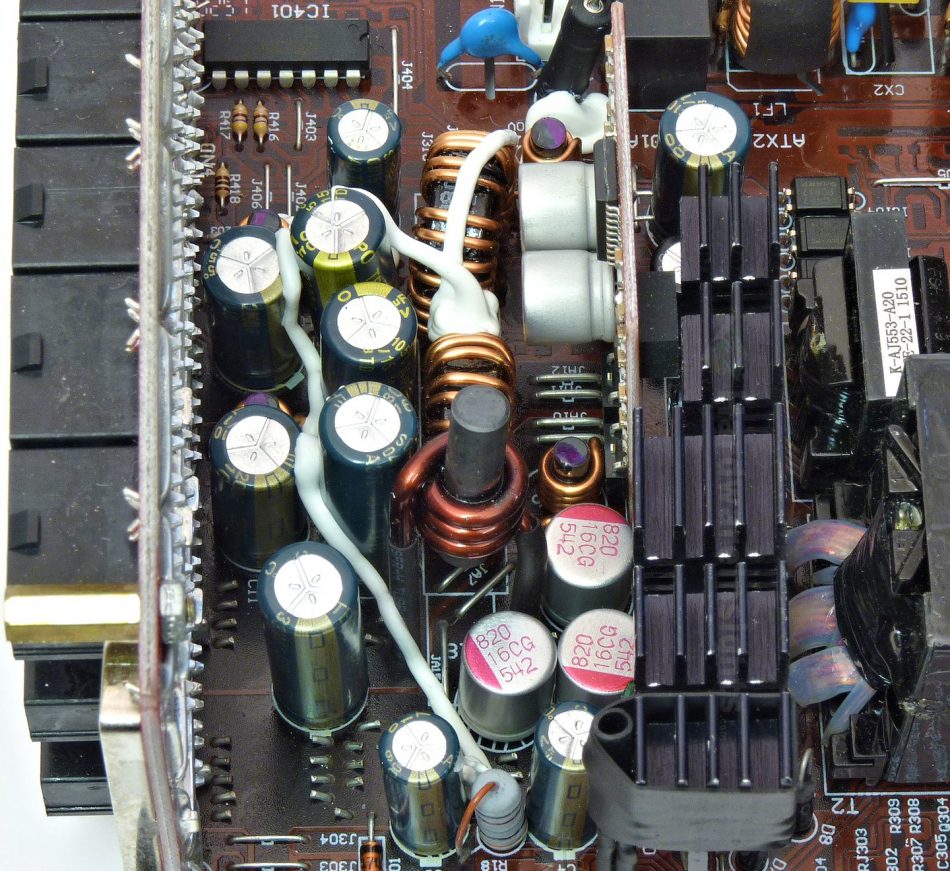

On the secondary side of the Volcano 750 Gold there are the rectification transistors, four pieces mounted to a common heatsink. They are the Infineon IPP015N04N G (120/400 A, 40 V, 1.5 mΩ @100 A) in TO-220 package. For the output filtering we can see three Teapo CG 820/16 polymers plus two more 470/16 on the DC–DC module board. The remaining two are custom SC wet electrolytics, 3300/16, that brings total capacitance to exactly 10 mF. The −12V rail has a special winding on the main transformer with two-way rectification and two 1000/16 SC caps.

The DC–DC module has the common Anpec APW7159C buck controller, which drives two pairs of transistors: Ubiq QM3004D (55/110 A, 30 V, 8.5 mΩ @10 V/30 A, 14 mΩ @4.5 V/15 A) in TO-252 package. The daughterboard has no heatsink or other measure of increasing surface area though the FETs are at least placed closer to the main board. So it can transfer the heat there through thick solder paths. Still, their RDS(On) is rather high, I think SAMA relies on today’s computers not actually drawing that much from +5/+3.3V rails here. However, somebody with a lot of hard-drives and USB devices or old, +5 V heavy system may pretty much bake the daughterboard alive. So for the secondary it will be only one extra point.

There is not that much filtering for the two rails, just a combination of SC 3300/10 and 2200/10 each time. Plus one 100/16 polymer on the modular board, that is not tha much, we’ll see how will the ripple look like. The fan regulator uses a thermistor sensor which drives UTC 2SD882 NPN transistor (3/7 A, 40 V) in TO-126 package. The secondary monitor is the Sitronix ST9S429-PG14, and besides providing the ordinary functions (Power Good, monitoring PWR On) it also monitors OCP, OVP, and UVP.

Build quality

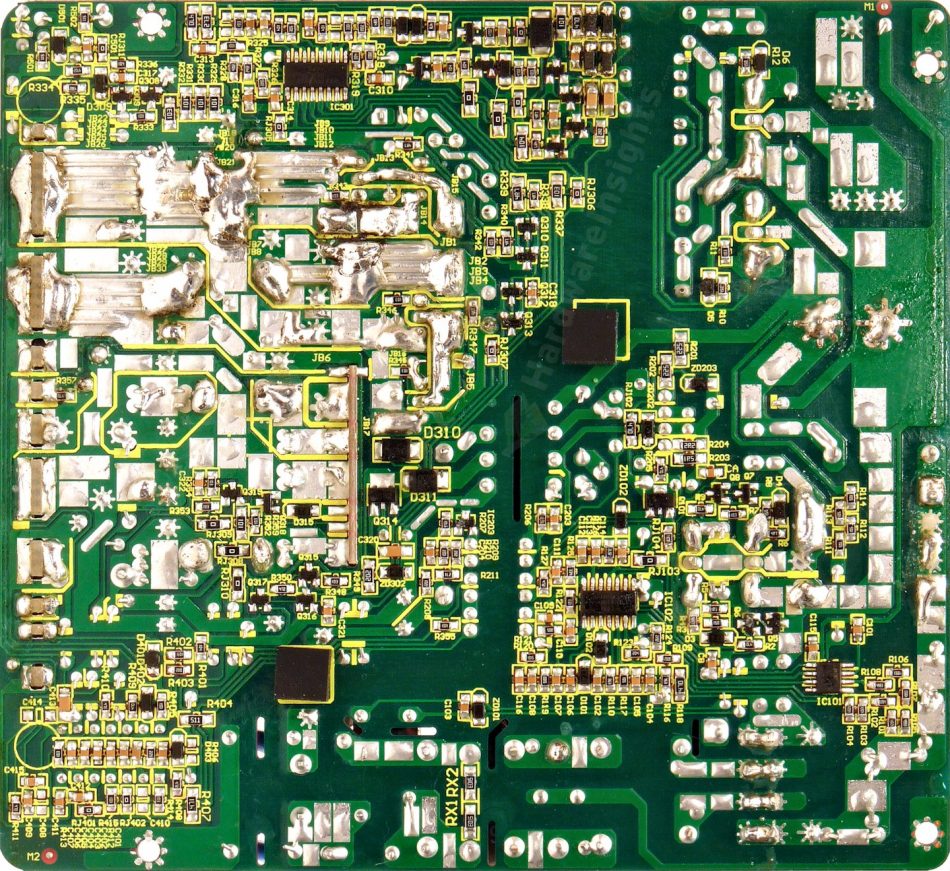

As usual, I’ll focus on the overall build quality and other things like electrical safety here, as the quality of the components that were used has already been discussed before. The separation between the primary and secondary side is good. As we are used to from SAMA, there is also some foam material under the primary side of the board. This time it is not flame-retardant, on the contrary it burns quite well. I do not understand why did they put it there. You can also notice two rubber spacers. The varistor is missing and thermistor does not have heatshrink tubing, but it is large and bypassed by a relay so it should survive long enough. As the board is quite large, there is usually space enough between the components so most of them do not have any extra insulation. SAMA used rather low quantities of silicone. Paths are reinforced by extra solder and on the secondary also wire jumpers plus more solder.

It seems however the soldering quality is quite poor. It is clearly visible absolute most of the spots which should have been covered by more solder only have tiny amounts. I am not sure if it is because of poor cleaning of the board, too fast travel through the soldering bath, or bad soldering flux, but the result is clearly visible. Some SMD components on the other hand have so much solder on their joints it created big balls of it. So way too many of the joints had to be manually resoldered which is not really that much better, some of them have huge amounts of solder, some of them still small, looks like workers responsible for that are kinda in a hurry. And look at all the soldering flux and other dirt. This is terrible. That mess is even across high-voltage paths on the primary side so if the flux degrades over time and becomes conductive, there are nice shorts across 380 V DC. The modular board seems to be soldered manually so you can also see the carnage.

Is seems somebody made a poor attempt to clean it as there is some evidence of brushing but they made it even worse. This is so bad I have to evaluate each independently otherwise I’d get lost in it. So we have −20 points for the incredibly bad soldering and −3 points for all the dirt. Many of the electrodes are also trimmed poorly and some almost touch and short to each other, that’s −5 points further. And those solder balls which go with the poor soldering, jeez. The modular board is pretty clean though it also seems it was cooled down too quickly. But many more balls were there. Altogether I found 13 small to medium balls, one really big one and some other mess. Another −15 points. Not even Enhance had such bad soldering and that was sometimes already pretty bad. I think that actually even the old Enermax units where they just left tons of soldering flux without any attempt of cleaning were not so bad, those at least were soldered properly and without solder balls. And it was a decade ago, too. So the overall result for this is −43 points.

For reasons explained later I got second sample so I also looked into that one. Overall the soldering is similarly poor; while SMD soldering is better, there is way more manually resoldered joints, and it sucks even worse than in the first sample. I found 9 solder balls of different sizes. I think this is equally bad to the first unit.