Locating the problem

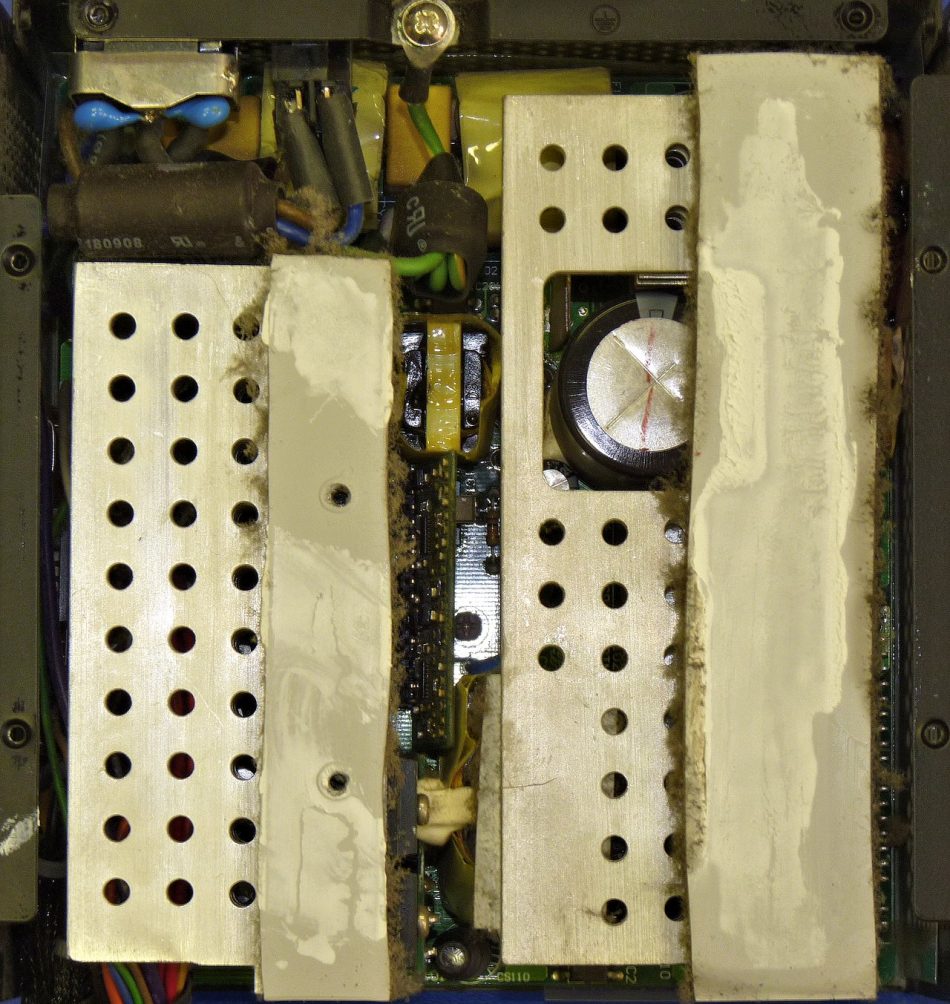

Upon removing the lid we can see the huge and thick heatsinks, thermally coupled with the lid/heatsink using thick silicone heat-conductive pads and zinc oxide/silicone thermal compound. After the years it already hardened so you can carefully remove the pads, clean them and prepare to apply new thermal compound. The main transformer is also coupled with the heatsink for cooling as it usually generates large amounts of heat.

You can already see the problem is with capacitors, note the small cap under the transformer. Almost all the capacitors in this unit went bad. FSP just does not care about the customers, even in this very expensive unit they put (Cheapo) Teapo SC and OST capacitors without hesitation. The only reason why this unit was somehow able to work for so long is that there is quite large combined capacity. Even failed caps usually keep some capacitance and with many of them in parallel, also supported by many quality caps on the motherboard and other devices, already failed units can somewhat work for some time.

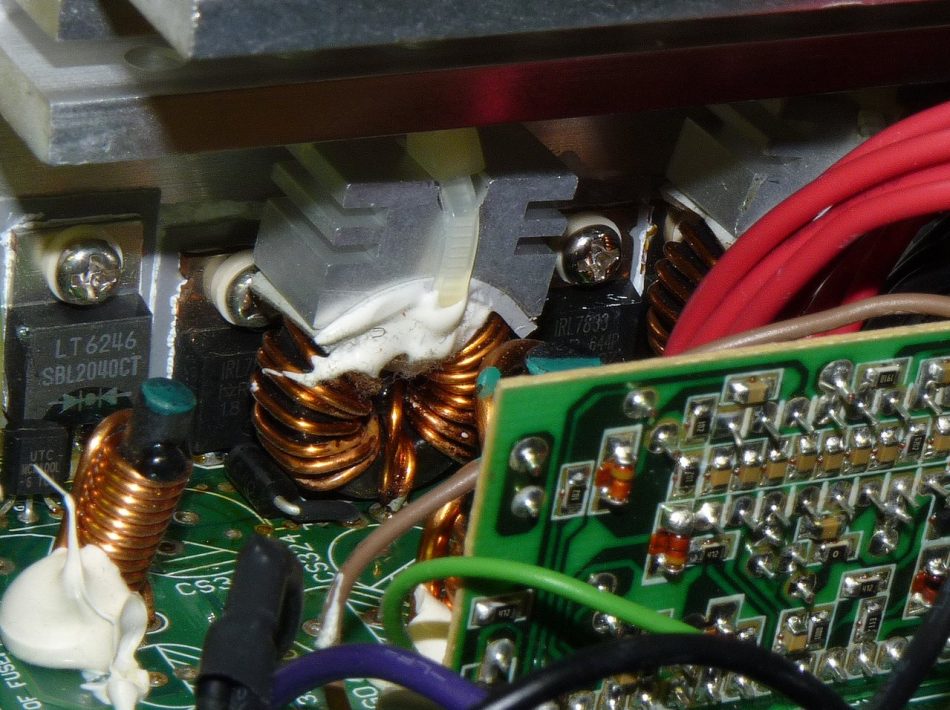

After removing them we can see the rectification transistors. Notice the output inductors, you can see they also waste considerable amount of power which FSP solved by sticking small heatsinks on top of them here.

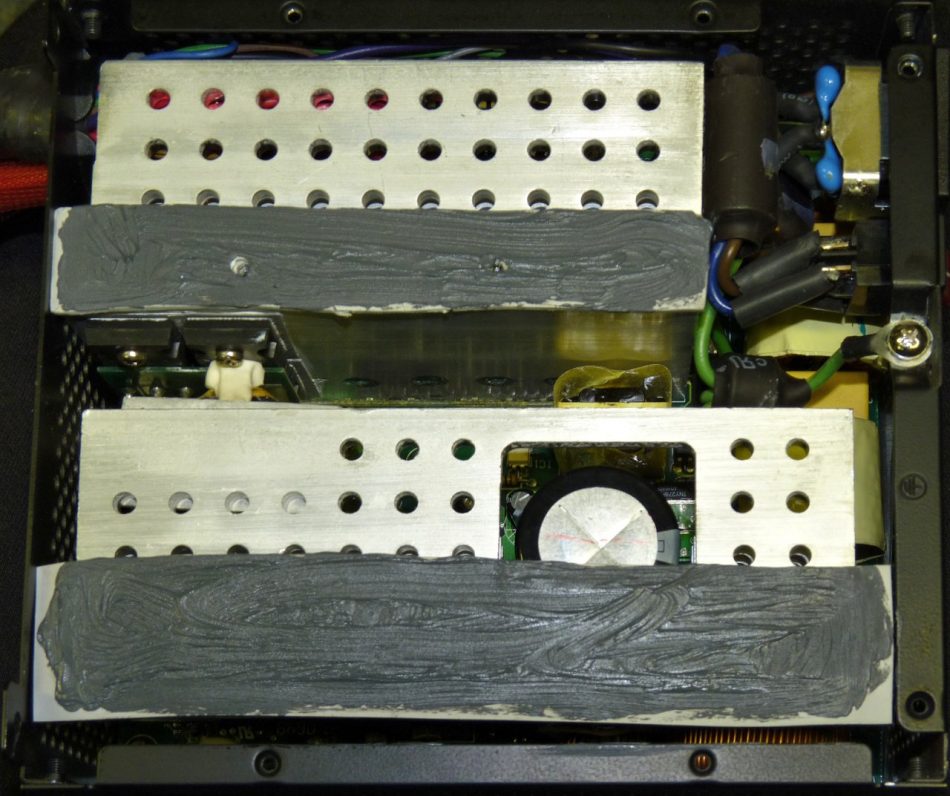

As there is little space under the heatsinks, from my stock I had to use Samxon RS 3300/16 which can only barely, but fit under. The Chemi-Con KZN 3300/16, 40 mm, are then put next to it as you can see. With twice the lifetime of the Samxon RS the unit should still work for a long time after the Samxons fail in the future.

The input Rubycon cap still measured very well within spec, though it may be good to check it again in few years. So, new thermal compound and we can reverse the procedure. After that the Calmer 560 is working like new.

Support Hardware Insights!

Or select from our donation goals!

Pages: 1 2