Contents

- 1Introducing the SilentiumPC Elementum E1 SI-350 (SPC124)

- 1.1Packaging and accessories

- 2Connectors & cabling

- 2.1Casing & cooling

- 3Input filtering

- 4Primary side

- 4.1+5 V stand-by rail

- 5Secondary side

- 5.1Build quality

- 6Load testing

- 6.1Loading +5 V SB

- 6.2Hold-up time

- 6.3Combined loading

- 6.4Combined loading ripple

- 6.5Crossloading, overloading

- 6.6Crossloading, overloading ripple

- 6.7Fan speed, temperatures and noise

- 7Conclusion and evaluation

- 7.1Thanks

- 7.2Discussion

Secondary side

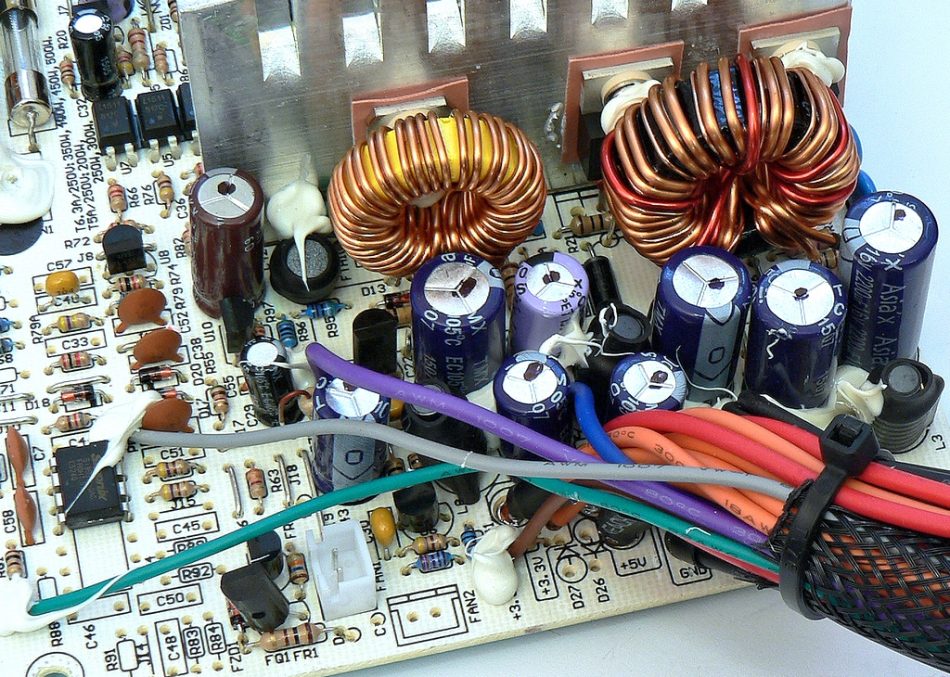

The secondary side uses schottky rectifiers for all three rails with the +3.3 V being generated from the +5 V using a magnetic amplifier (magamp). There are two PFC Device Corporation PFR20L60CT (20/180 A at 60 V, drop of 0.65 V at 10 A and 25 °C, 0.56 V at 125 °C) in parallel for the +12 V rail. The +5V rail has a PFR30L30CT (30/280 A at 30 V, 0.39/0.47 V at 15 A), and the +3.3 has an ST Micro STPS30L45CT (30/220 A at 45 V, 0.67/0.74 V). Everything comes in TO-220 packages mounted on a common secondary heatsink.

The capacitors are Asia’X, mostly a combination of 2200 μF before and 1000 after the Pi coils. The secondary supervisor is only an 8-pin IC, though there is a position for a full 14pin one. The Sitronix ST9S313-DAG is used which can only monitor UVP, OVP, PWR On signal and provide a PWR Good signal. The best this unit can achieve is perhaps some kind of OPP, and there’s no way it has a working OCP implementation. So the statement about OCP on the label is not true. The thermistor probe that senses the temperature for the fan speed controller is attached to the secondary heatsink using silicone.

Build quality

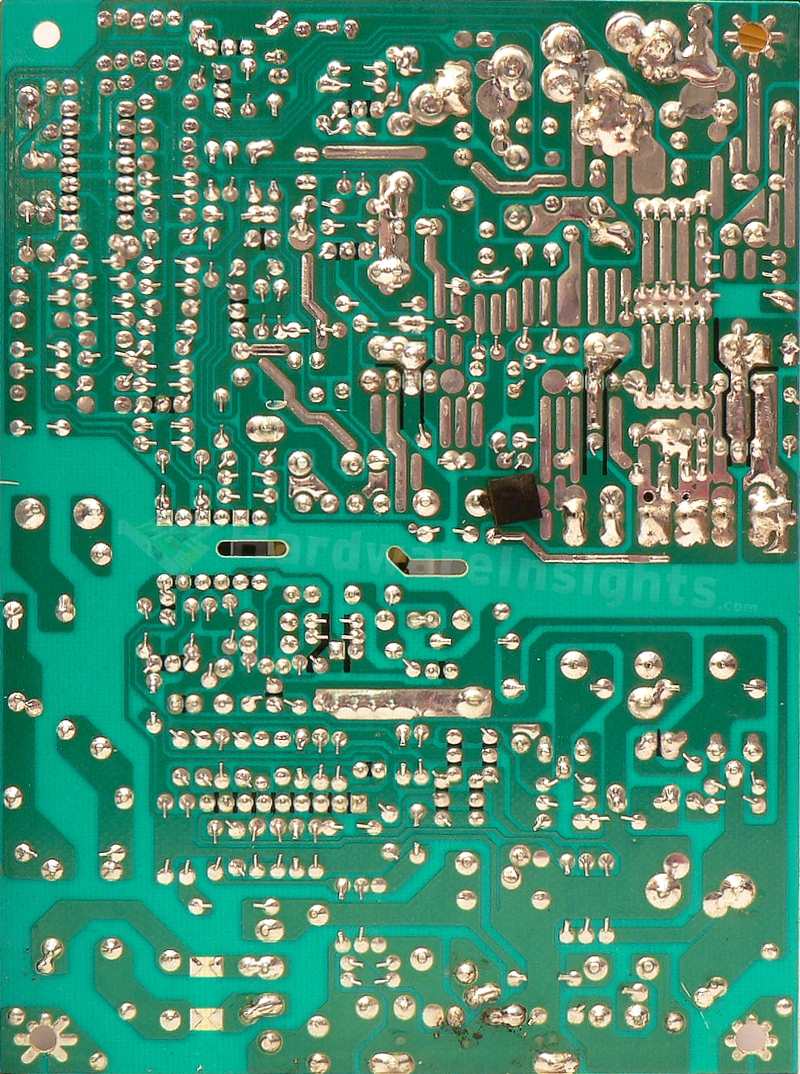

As usual, I’ll focus on the overall build quality and other things like electrical safety here, as the quality of the components that were used was already discussed before. The separation between the primary and secondary sides is good. The varistor is sleeved with heatshrink while the thermistor is not. Overall there is not much extra insulation, but reasonable amounts of silicone are used to hold components in place. You can clearly get the feeling that this is a budget unit that was most likely produced on an older manufacturing line as there are mostly through-hole components as opposed to SMD. The design is clean though, but the wave soldering could use some improvement. Some of the joints indicate that they might have a tendency to crack over time, forming cold joints. But for the price, I think it is OK as it should survive for at least two years.

There are some manually-resoldered joints on the primary side that nobody cleaned afterwards which should be a must, considering the very high voltages present here. Overall it is not bad, and there’s some reincoforcement of the secondary side rails with both solder and jumper wires. I only found a single piece of stray solder, which was actually stuck in a blob of resin. That’s a very good result for a unit with such a low price so I think the unit will retain all its points here.