Contents

- 1Introducing the Topower SilentEZ 350W

- 1.1Packaging and accessories

- 2Connectors & cabling

- 2.1Casing & cooling

- 3Input filtering

- 4Primary side

- 4.1+5 V stand-by rail

- 5Secondary side

- 5.1Build quality

- 6Load testing

- 6.1Loading +5 V SB

- 6.2Hold-up time

- 6.3Combined loading

- 6.4Combined loading ripple

- 6.5Crossloading, overloading

- 6.6Crossloading, overloading ripple

- 6.7Fan speed, temperatures and noise

- 7Conclusion and evaluation

- 7.1Thanks

- 7.2Discussion

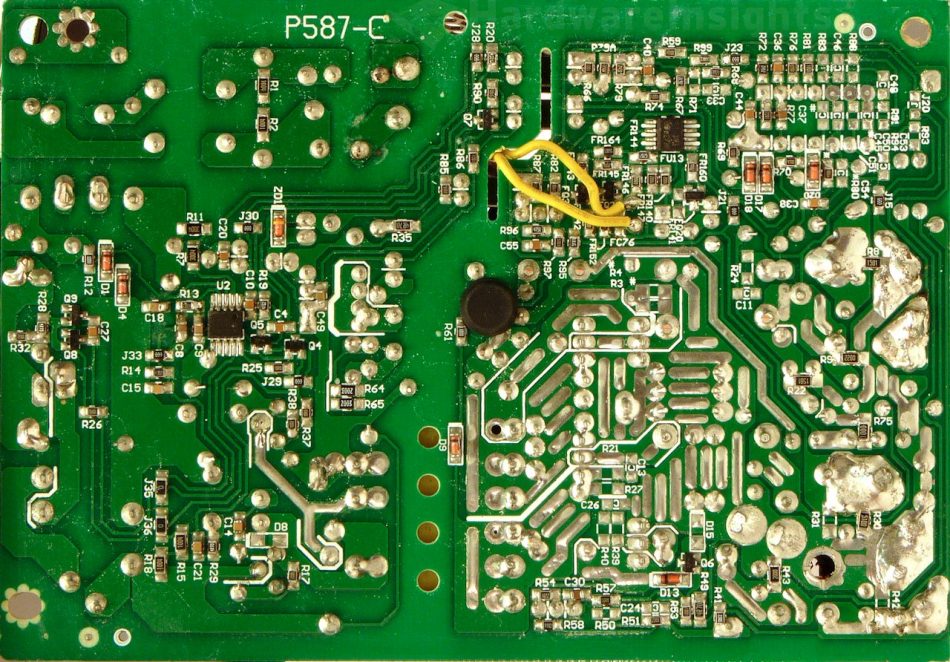

Secondary side

The secondary side of the SilentEZ 350W uses the standard set for somewhat more decent units aimed at higher efficiency: Schottky rectifiers for all the rails. Both the +3.3 and +5 V have ST Micro STPS30L45CT (30/220 A at 45 V, 0.74 V at 30 A and 25 °C, 0.67 V at 125 °C) in TO-220 package. The +3.3V rail itself uses magnetic amplifier (or magamp) to create the voltage from the +5V rail transformer output. The +12V output has two rectifiers in parallel, the STPS20H100CT (20/250 A, 100 V, 0.88 V @20 A and 25 °C, 0.73 V @125 °C) also in TO-220. You can see a small thermistor probe squeezed between the fan header and the secondary heatsink, with some thermal compound on it.

The inductors seem to have reasonably sized cores and winding for 350W. Filtering consists of more Hermei 1000/16 caps, two for +3.3 and +5 V, one for −12 V, three for +12 V. There is one on the inductor output, then two Pi coils and one after each coil. There are feedback lines from both these +12V “rails” so it is possible the inductors, if having precise enough resistance specification, could act as current shunts. However, the feedback components are missing and instead of full-sized secondary supervisor, there is only the very basic 8-pin Silicon Touch Technology PS113. So there is NO OCP capability in this unit and it would be interesting to see if OPP actually works. To conduct the power to the modular board, Topower chose 14AWG wires, at least something is decent here.

Build quality

As usual, I’ll focus on the overall build quality and other things like electrical safety here, as the quality of the components that were used was already discussed before. The separation between the primary and secondary sides is good, there is even some extra creepage slot under the optocouplers and some openings under the main transformer for extra cooling. The thermistor is not sleeved with heatshrink. There is also a rubber spacer to support the board, though it is not that heavy. What is terrible is that yellow wire which goes around the AC conductors, then through the isolation slot and finally connects to the secondary. It’s that button thing to switch the fan for full speed. What the hell is this crap supposed to be?! Some electrical safety, nothing?! Some fool just came up with that button idea so they took complete design and soldered two wires in there like this! Topower must be kidding me.

The soldering itself is no wonder either, it is well below average. Many joints, including SMD components, have been manually resoldered. The output cabling seems to be resoldered as a whole. Yet still many joints still wait for proper resoldering. As usual, nobody cleaned the unit afterwards so there is not only soldering flux residue, but also solder balls and other pieces of solder here and there (I counted five). And also look how dirty the board is even away from any solder joints. Not to mention Topower still used chloroprene glue in large quantities. As soon as the components, especially resistors, inductors etc. start heating, the glue will start degrading, corroding the conductors and later it will even become conductive. From the first second you turn the SilentEZ 350W on, its clock starts ticking before it dies. I know we are in low-end, but still this is so bad, I have to remove at least five points.