Contents

- 1Introduction

- 1.1Packaging and accessories

- 2Connectors & cabling

- 2.1Casing & cooling

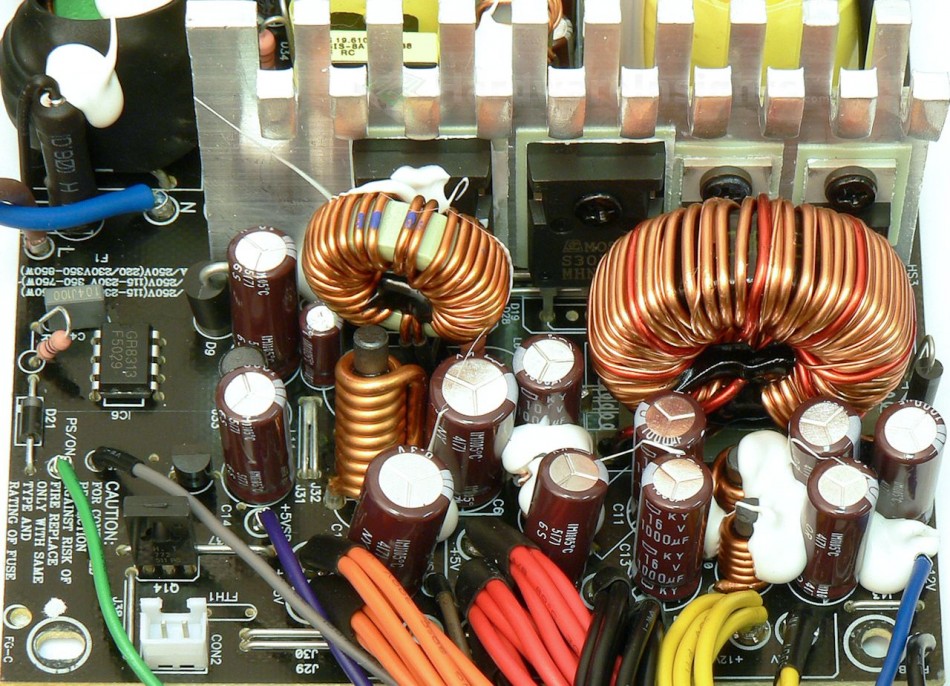

- 3Input filtering

- 4Primary side

- 4.1+5 V stand-by rail

- 5Secondary side

- 5.1Build quality

- 6Load testing

- 6.1Loading +5 V SB

- 6.2Voltage hold-up time

- 6.3Combined loading

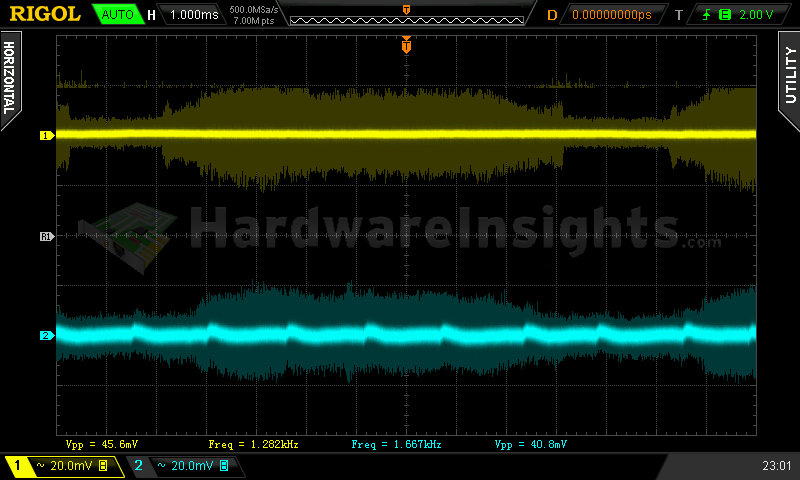

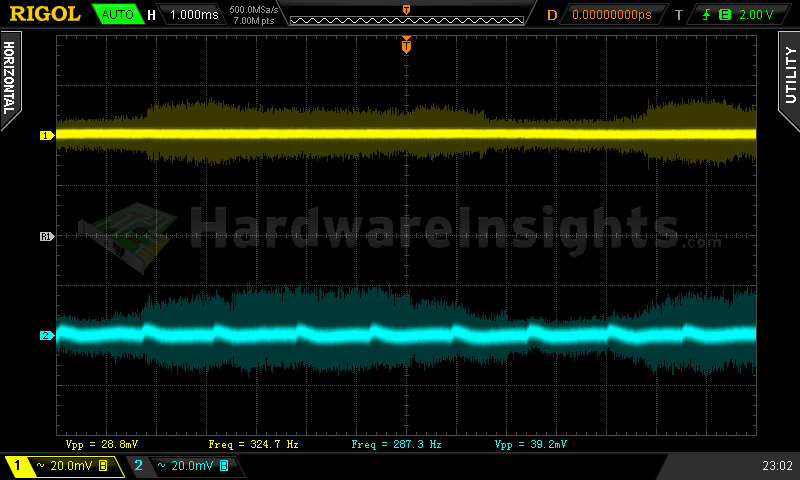

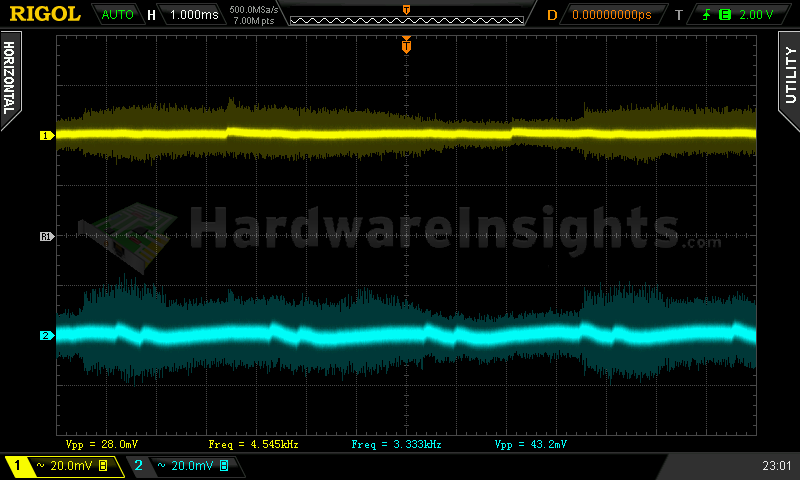

- 6.4Combined loading ripple

- 6.5Crossloading, overloading

- 6.6Crossloading, overloading ripple

- 6.7Fan speed and temperatures

- 7Conclusion and evaluation

- 7.1Thanks

- 8Addendum - working on the unit

- 8.1Discussion

Addendum – working on the unit

As with the Seasonic S12G 550 W prototype, once again we have too high ripple for the unit to pass so once again I will have a look on it. I decided for increasing the output filtering capacity by installing the Chemi-Con KYA 3300/6.3 capacitors I have which have both higher capacity and lower ESR than the original KY 1000/10. These were installed on the +5 V SB rail and +3.3 V rail, while the original 2200/6.3 from +3.3 V have been installed on the +5 V rail. However, this itself did not do the trick.

I have thought about using polymer capacitors on the +5 V SB supply instead of those KYA 3300/6.3 as they still have somewhat higher ESR and may not cope so well with high-frequency ripple. Obviously the problem was not that much capacity related. But than I realized I have actually not added that sixth ceramic Y capacitor between primary and secondary sides in the vacant spot the first time. So I have used approx. 3.3 nF capacitor for that task.

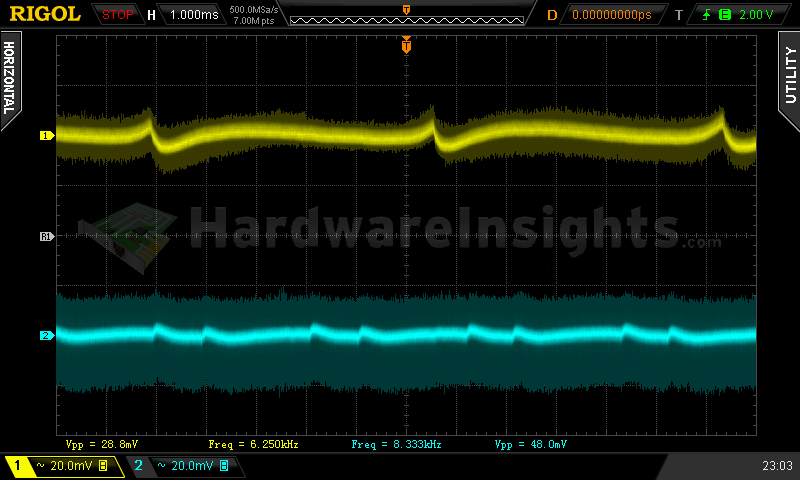

Than I also noticed some vacant spots for SMD capacitors (or maybe resistors) on the stand-by rail tracks so I used my remaining ~8 μF capacitor for this rail. These two more changes already lowered the high-frequency ripple by more than 50 % so now the unit is finally in spec. Actually the ripple on most of the rails dropped by a considerable margin. The testing is done under full load (test number 6) where the ripple was the worst.