Contents

Computer LCD monitors are probably one of the most typical examples of Planned obsolescence, also called Warranty engineering. Even though sometimes the whole display is poorly designed (like BenQ FP737), the easiest, cheapest and most common method used for this purpose are of course electrolytic capacitors which are, after almost a century of massive usage, very well known devices. As a result, manufacturers can plan average lifespan with 6-12 month precision based on average usage, temperatures etc. But since this is the first of this kind of article here on Hardware Insights, let’s do some introduction first.

Troubleshooting – identifying the problem

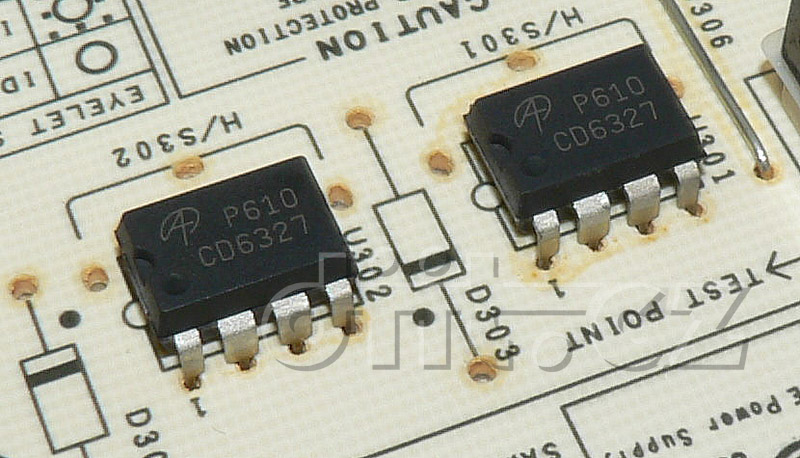

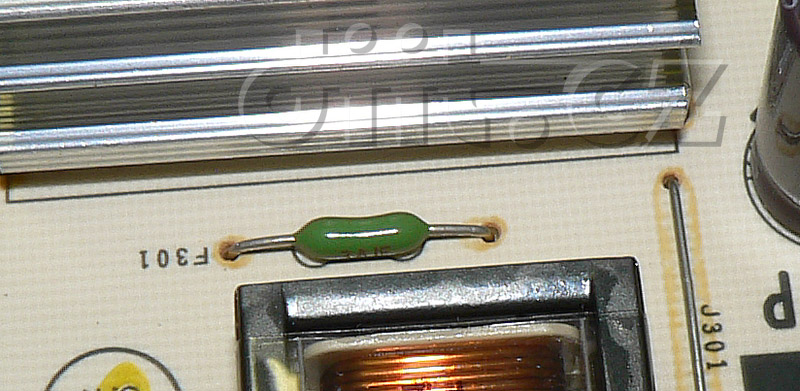

The most problematic area – or area where problems are usually visible first (even though this is not the root) – are the inverters for backlighting. An LCD itself does not produce light – it only works with it, so it needs a separate light source. Even though monitors with LED backlighting are now becoming more popular, CCFL-backlit devices are still common. Sometimes the transformers go bad, sometimes transistors short, sometimes even just current spikes occur, burning a fuse. But in up to 80 % cases (according to my observations, there is no hard-statistics), electrolytic capacitors are the primary cause. Bad capacitors lose their ability to filter ripple, causing the switching transistors to get excessively loaded (and often overheat as a result) and short as the driving circuitry tries to regulate its output power despite the excessive ripple they must work with. Sometimes they blow a fuse because of current spikes.

Example of inverter transistors

Physically broken panels (which are made on glass substrate, thus fragile) or CCFL tubes (also from glass) are not possible to repair, they must be replaced piece by piece. The other problems are mostly from bad inverter transformers, bad/loose connection of CCFL (cold/rotten joints on cables directly on CCFL tubes which require dismounting the LCD piece-by-piece), shorted semiconductors, bad TCon/signal boards (mostly impossible to repair here) and other, hard-to-find problems.

Typical and (mostly) easy-to-repair problems are:

- Picture/backlight blinking

- Backlight intensity waving

- Self-restarts while turning on/working or the need to restart for some time until the picture “catches” (often called “the need to warm up”)

- No picture, but LED shines (no backlight, you can see picture when you light the display using flashlight)

- LED is blinking, display restarts

- 2-seconds-to-black (picture appears briefly and then disappears)

- Completely dead

The first three points usually precede the latter four. If that is already happening, then do not leave it be and don’t push the button for minutes to work around it. It will only get worse and eventually end with some of the worse problems. Those are mostly just bad capacitors but when the stress on transistors or fuse gets over a certain point, you will end with a black screen. This happens when the fuse blows, or in newer designs, the driving circuitry identifies a problem and goes into protection mode, turning the whole inverter off.

If some of the transistors short, then the whole power supply usually goes into protection mode and nothing will work. The same can happen when the capacitors are sooo bad it is not able to operate at all. It may also cycle on and off again as the load spikes, making short protection kick in. The same may happen if there is a problem with an inverter transformer or backlight tube which results in uneven distribution of power, making protection kick in and turning off the inverter.